Features

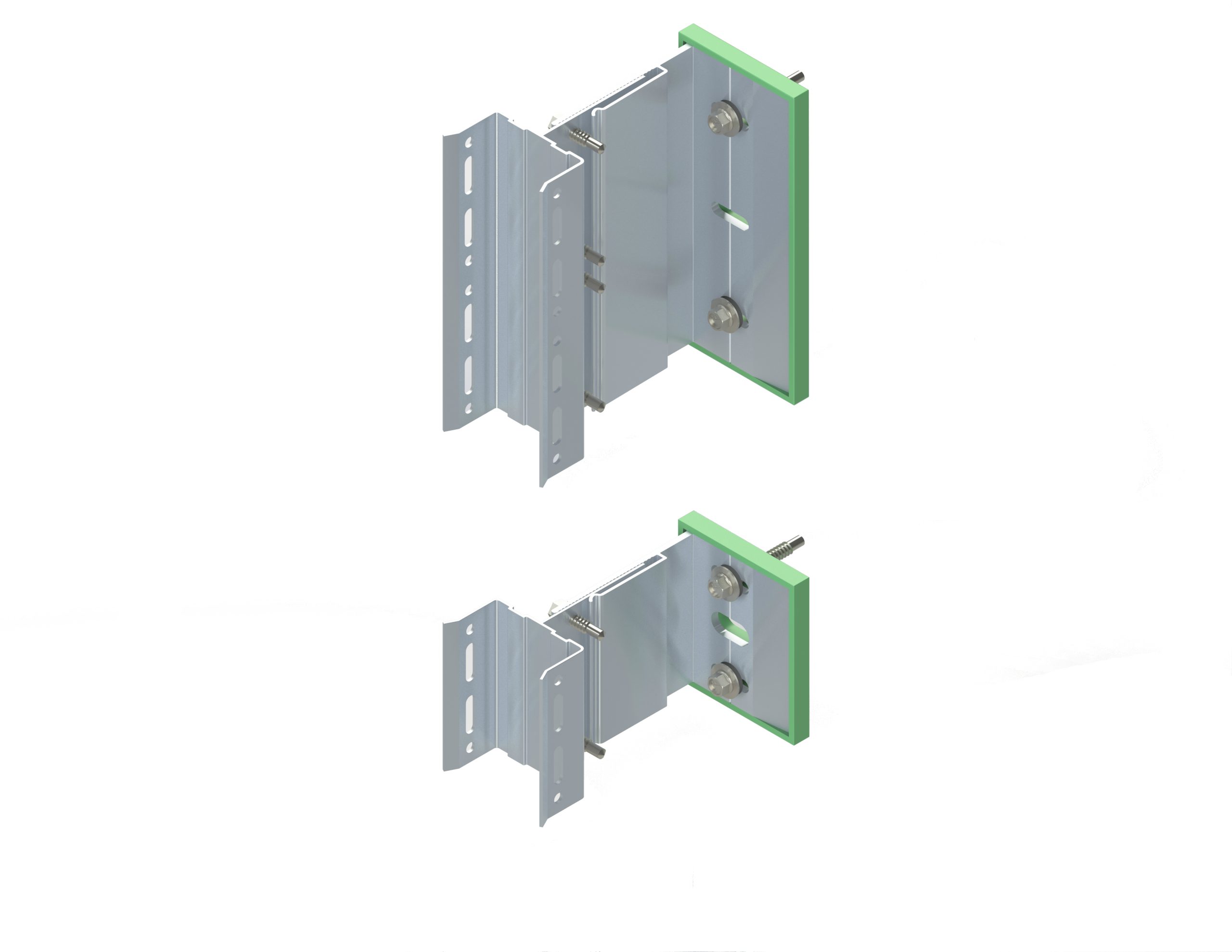

- NV6 is the NVELOPE subframe system suitable for supporting a timber batten (to support vertical and/or horizontal cladding elements).

- Timber batten can be used to support timber cladding/weatherboarding and ply.

- NVELOPE fixed and sliding points located on the NV6 adapters allow for expansion and contraction.

- NVELOPE bracket spacing is determined by cladding options such as the dimensions and weight of the facade cladding, local wind loads.

Supports

- Vertical timber cladding: vertical timber battens are supported with NVELOPE carriers brackets fixed back to NVELOPE support brackets.

- Horizontal timber cladding: vertical timber bearers are supported with NVELOPE carriers fixed back to NVELOPE support brackets, then counter battened.

Material

The selection of materials to use in the construction of a subframe system within a rainscreen façade is of paramount importance. Material choice can also affect the thermal performance of the overall rainscreen in addition to engineering assurance.

Aluminium

- Aluminium subframe systems for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 9 – Parts 1-4

- Aluminum is the second most widely used metal after iron and as such has a robust and well defined UK and international supply chain

- Its low weight and high strength ratio and simplicity of fabrication either on site or within a manufacturing setting ensures it is an ideal material with which to create high performance rainscreen subframe systems for cladding applications.

- Aluminium is inherently corrosion resistant however this can be complemented and further improved by additional treatment including anodization whilst still maintaining a Euroclass A1 fire rating.

- NVELOPE systems only use the superior 6005 T6 alloy which provides superior strength and performance over and above other commonly used aluminum.

Stainless Steel

- Stainless steel subframe bracket systems for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 3 – Table 5.1

- NVELOPE stainless steel brackets are only manufactured from a superior 316 grade of alloy to provide an outstanding level of resistance to localised corrosion such as maritime and polluted areas.

Sustainability

Sustainability is a key factor in the design of any building. Identifying the right material from a sustainable manufacturer with a credible supply chain and responsible sourcing is crucial. At SFS:

- The aluminium we manufacture from is 100% recyclable

- The alloy we use is made from 100% re-melted material

- 6063 alloy as used by many other sub frame manufacturers’ can only utilise 40% recycled scap due to global shortages.

- CO2 production as a consequence of extrusion alone estimated at 0.35 – 0.5Kg per Kg currently.

Options

- Utilising our proven technology of Project Builder Thermal you can enable any project to be optimised for performance and budget. Whether a lower or a higher thermal performance is required our Thermal Solutions range offers the ability to fine tune your project requirements.

- NVELOPE brackets allow for adjustment between the face of the primary support to outer face of vertical profiles.

- Green isolators (hard polypropylene isolator) assembled as standard, allowing rainscreen installations to benefit from the low thermal conductivity values associated with reduced thermal bridging within the design.

Reviews

There are no reviews yet.